A chainsaw bar is worn out if it shows significant signs of wear, such as a narrow or uneven rail. Excessive heat marks or a loss of straightness can also indicate it’s time for a replacement.

Maintaining a chainsaw is critical for both safety and the longevity of the equipment. A key component that requires regular inspection is the chainsaw bar. Over time and with consistent use, this part can wear down, compromising the tool’s performance and safety.

Recognizing the signs of a worn-out chainsaw bar enables owners and operators to undertake timely replacements, ensuring the chainsaw functions effectively during use. Promptly addressing bar wear helps maintain cutting precision and operational safety. As a vital aspect of chainsaw maintenance, understanding and identifying bar wear is an essential skill for any user aiming to get the best out of their equipment.

Signs Of A Worn Out Chainsaw Bar

Chainsaw bars endure a lot of stress during cutting. Knowing the signs of wear is key to maintaining a safe and efficient tool. Spotting the signs early can save time and money. Look for these clear indicators to determine if a chainsaw bar needs replacing:

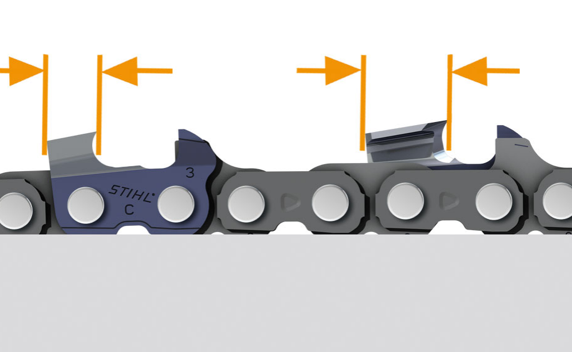

Visible Groove Damage

The bar has a groove that guides the chain. Check the groove for signs of wear. Look for:

- Flattening or widening of the groove bottom

- Shallow grooves making the chain loose

- Noticeable bumps or burrs inside the groove

If these issues are present, the bar might not hold the chain correctly. This leads to decreased performance and increased danger.

Uneven Cutting Edge

Uneven edges on the bar are a sign of wear. Inspect the cutting edge. Look for:

- Dents or warping on the edge

- Chain cuts that slant or drift

If cutting becomes difficult or the bar looks uneven, consider a replacement. This ensures clean cuts and reduces strain on the chainsaw’s motor.

Regular maintenance includes examining the bar. Replace the bar at signs of severe wear. This keeps the chainsaw efficient and safe for every use.

Credit: blog.stihl.co.uk

Measuring Bar Wear

A clear sign that a chainsaw needs attention is bar wear. Regular checks are vital to ensure safety and efficiency. Recognizing when a bar is past its prime involves simple measurements.

Bar Groove Gauge Use

The chainsaw bar’s groove holds the chain in place during use. Check groove depth with a bar groove gauge. Place the gauge tool inside the bar’s groove. If the gauge fits loosely, the bar may be worn. Repeat this at different bar points.

Wear Limit Markers

Look for markers indicating wear limits on your chainsaw bar. These are manufacturer-provided indicators. When the bar wears down to these marks, it’s time for a replacement. Ignoring these can lead to dangerous chainsaw operation.

- Inspect visually: Look for wear limit markers along the bar’s edge.

- Compare wear: Measure the distance from the edge to the wear limit marker.

- Make a decision: If close to or past the marker, consider replacing the bar.

Physical Symptoms During Use

As your chainsaw slices through wood, the performance can tell you a lot about its condition. Regular users might notice change over time. Understanding these ‘Physical Symptoms During Use’ helps you to spot wear before it becomes a more significant issue. Pay attention to the following signs.

Excessive Vibrations

Excessive vibrating tells a story of a bar that could be nearing its end. A well-conditioned chainsaw should run smoothly; noticeable shaking suggests trouble. These vibrations can wear on both the saw and its user. Seek out these signs:

- The bar’s edges look uneven or bent.

- Chain movement feels rough or jumpy.

- Unfamiliar noises or rattling occur during operation.

Difficulty Maintaining A Straight Cut

When cuts wander, this might point to a worn-out bar. A straight cut should be a cinch with a good chainsaw. Here is what to observe:

- Check if the chainsaw pulls to one side sharply while cutting.

- Inspect the bar for any signs of warping or bending.

- Examine the chain’s tightness; too much give can also cause irregular cuts.

Sharper tools produce predictable cuts. When precision drops, assess your bar straight away. Staying ahead of wear means safer, more efficient work.

Evaluating The Sprocket And Chain For Uneven Wear

It’s crucial to check your chainsaw bar and chain regularly. Uneven wear can lead to poor performance and even safety hazards. In this section, you’ll learn how to assess the sprocket and chain for signs of wear that might suggest it’s time for a replacement.

Sprocket Inspection

Inspect your sprocket often. Look for these clues:

- Deep Grooves: If the sprocket has deep grooves, it’s worn out.

- Sharp Edges: Sharp edges on sprocket teeth mean they’re wearing down.

- Uneven Teeth: Teeth should be even. If not, replace the sprocket.

A shiny sprocket indicates excessive wear. Check for wobble too; a stable sprocket is vital for safety and performance.

Chain Stretch And Dullness

A chain that’s stretched or dull can cause your chainsaw to work harder and be less effective. Look out for these signs:

- Check Chain Tension: If the chain’s too loose even after tightening, it may be stretched.

- Examine for Dullness: Dull chains don’t cut efficiently. They need sharpening or replacing.

- Measure Chain Wear: Use a ruler to check the drive link’s length. If it’s longer than the manufacturer specification, get a new chain.

Remember, a stretched or dull chain can strain your chainsaw’s engine and increase the risk of kickback.

Maintenance Tips To Extend Bar Life

Maintenance Tips to Extend Bar Life are crucial for any chainsaw user. Regular upkeep not only ensures optimal performance but also prevents premature wear and tear. Below are essential practices to get the most out of your chainsaw bar.

Regular Cleaning

Keeping your chainsaw bar clean is essential. Dirt and sawdust can cause excessive wear. Follow these steps:

- Remove the bar from the chainsaw.

- Use a soft brush to dislodge debris.

- Wipe the bar down with a clean cloth.

- Clean the groove with a bar cleaning tool.

Regular cleaning after each use helps maintain performance and longevity.

Proper Lubrication Practices

Appropriate lubrication reduces friction and wear. Use these best practices:

- Always use the recommended bar and chain oil.

- Check the oil level before each use.

- Ensure the oiler is functioning correctly.

- Apply oil to the bar’s nose sprocket if necessary.

Proper lubrication ensures smooth operation and extends the bar’s life.

Replacing Vs. Repairing Chainsaw Bars

Knowing when to replace or repair a chainsaw bar is crucial for effectiveness and safety. Chainsaw bars endure a lot of stress and wear over time. It’s often a dilemma to choose between fixing an old bar or getting a new one. Identifying the right course of action saves time and money.

- Bow in the bar: Indicates metal fatigue.

- Worn out rails: Creates cutting inaccuracies.

- Cracks or breaks: Poses a safety hazard.

- Excessive heat damage: Weakens the bar structure.

Worn out bars compromise performance. Replace when signs of damage hinder safe operation. Regular inspections prevent unexpected failures.

Minor wear can often be fixed. Regular maintenance extends bar life.

| Repair / Adjustment | Description |

|---|---|

| Bar Truing | Straightens the bar for better cuts. |

| Rail Grinding | Smoothes the rails and removes burrs. |

| Tip Replacement | Renews the sprocket for smoother rotation. |

Guide bar maintenance tools are available. Use these tools to keep the bar in top condition.

The Risks Of Ignoring Bar Wear

Chainsaws are powerful tools for cutting and trimming. Regular maintenance keeps them safe and efficient. A worn-out chainsaw bar poses risks. It’s essential to stay alert to the signs of wear. Recognizing these issues can prevent accidents and maintain performance. Let’s explore the dangers of overlooking bar wear.

Safety Hazards

Safety should always come first with chainsaw use. Ignoring the wear on your chainsaw bar can lead to serious risks:

- Increased kickback potential – A worn bar can cause the chain to move unpredictably.

- Loss of control – When the bar is not straight, controlling the cut becomes harder.

- Possible equipment failure – This can happen mid-use, leading to injuries.

Impact On Chainsaw Performance

A worn bar does not just pose safety risks. It also affects how a chainsaw performs. Here are some performance issues to watch for:

- Uneven cuts – A damaged bar can result in cuts that are not straight or clean.

- Extra strain on the engine – This occurs because of the poor cutting action.

- Inefficient cutting – This results in wasted effort and longer job times.

Credit: www.chainsawsculpture.co.uk

Choosing The Right Replacement Bar

Choosing the right replacement bar for your chainsaw is essential. The bar is critical for precise cutting. A worn-out bar can decrease your chainsaw’s effectiveness and pose a safety risk. To ensure optimal performance, find a compatible and high-quality replacement. This guide will help you select the perfect bar for your chainsaw.

Compatibility With Chainsaw Model

Check your chainsaw model first. Not all bars fit every chainsaw. Your chainsaw’s manual lists compatible bar sizes and types. Matching the right bar to your model ensures your chainsaw performs well. Look at these compatibility factors:

- Bar length – Must suit your chainsaw’s power and intended use

- Slot gauge – Must fit the chain’s drive link thickness

- Mount type – The bar’s attachment point must align with your chainsaw

Quality And Material Considerations

Quality matters for a replacement bar. Higher quality means longer bar life and better cuts. Materials like steel are common in chainsaw bars for their durability. Consider these points:

- Material type – Look for solid steel with high-quality welding

- Coatings – Should resist corrosion and minimize friction

- Brand reputability – Trustworthy brands often guarantee quality

Step-by-step Guide To Replacing The Bar

Chainsaw bars endure a lot. Over time, they can wear out. When they do, snags or poor cutting can occur. This guide simplifies the bar replacement process.

Tools Needed For Bar Replacement

Before starting, gather these tools:

- Screwdriver – For removing screws.

- Socket wrench – To adjust nuts and bolts.

- Torque wrench (optional) – Ensures proper tightness.

- Cleaning brush – Cleans the chainsaw’s interior.

- New chainsaw bar – The replacement part.

Removing And Installing A New Bar

- Power Down the chainsaw. Ensure its engine cools down.

- Remove the chain cover. Use the screwdriver to loosen screws.

- Release tension. Loosen the chain tensioner for easy removal.

- Clean the internals. Use the brush to remove any debris inside.

- Remove the old bar. Slide it out carefully.

- Align the new bar. Place the new bar where the old one sat.

- Replace the chain. Ensure it fits snugly around the new bar.

- Restore tension. Tighten the chain but not too much.

- Replace the cover. Use the screwdriver to secure the chain cover.

- Final check. Ensure everything is tight and secure.

With these steps, your chainsaw is ready. Test it carefully. Proper maintenance ensures safety and efficiency.

Expert Tips For Preventing Premature Bar Wear

An essential aspect of keeping your chainsaw in top condition involves preventing bar wear. It saves time and money. Proper care ensures efficiency and safety. Discover expert tips for preserving your chainsaw bar.

Proper Chainsaw Techniques

Using the right techniques extends the life of a chainsaw bar. Focus on these practices:

- Guide with care: Avoid forcing the bar through wood.

- Right pressure: Use enough pressure to engage the chain, not more.

- Even use: Rotate the bar regularly to distribute wear.

Regular Maintenance Schedule

Consistent maintenance prevents complications. Implement these checks:

- Clean regularly: Remove debris after each use.

- Inspect the bar: Look for signs of wear or damage.

- Lubricate: Keep the bar and chain well-lubricated.

Credit: blog.stihl.co.uk

Frequently Asked Questions For How Do You Know If A Chainsaw Bar Is Worn Out

How Can You Tell If A Chainsaw Bar Is Bad?

Check the chainsaw bar for signs of wear, unevenness, or damage. A bad bar may have deep grooves, bends, or cracks. Uneven wear can affect cutting accuracy and safety. Replace the bar if you notice these issues.

What Wears Out On A Chainsaw Bar?

Chainsaw bars wear out due to frequent use, heat, and improper lubrication. Key wear points include the bar’s rails and the groove that houses the chain. Regular maintenance can extend the bar’s lifespan.

How Do I Know When My Chainsaw Chain Needs Replacing?

Replace your chainsaw chain if it’s dull despite sharpening, the teeth are visibly damaged or missing, or cutting becomes difficult and inefficient.

How Long Does A Stihl Chainsaw Bar Last?

A Stihl chainsaw bar typically lasts 1-3 years with regular use, depending on maintenance and cutting conditions. Proper care can extend its lifespan.

Conclusion

Recognizing the signs of a worn chainsaw bar is essential for effective and safe operation. Check for uneven wear, cracks, or a loose chain regularly. When these symptoms appear, it’s time for a replacement. Stay ahead of equipment maintenance to ensure peak performance and protect your safety.

A diligent caretaker keeps their chainsaw in top condition.